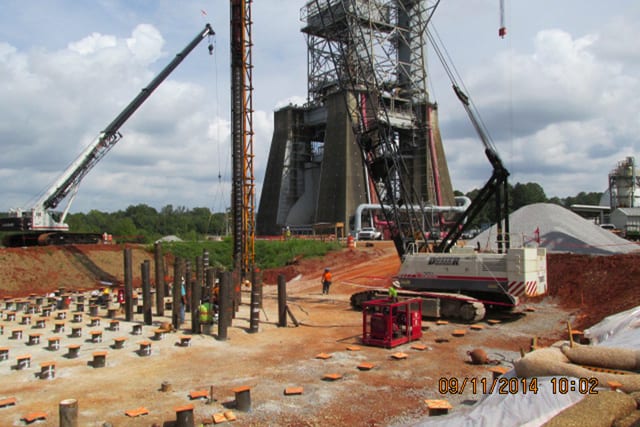

Pile Driving, Drilling And Full Service Pile Contractor

Safety. Quality. Schedule.

Founded in 1996, American Deep Foundation, Inc. (ADF) is a contractor specializing in pile driving, augered piles, micro piles and excavation bracing and is staffed by a group of individuals with an extensive background in the pile and shoring industry. The office and field personnel are a good combination of experienced professionals who have experienced the developments in the pile industry and young aggressive professionals who enjoy the challenge of bringing a project ahead of schedule with safety and quality.

info@AmericanDeepFoundation

GEORGIA OFFICE

info@AmericanDeepFoundation.com

NORTH CAROLINA OFFICE

ABOUT US

10 Piles to 10,000 – Big or Small

Founded in 1996, American Deep Foundation, Inc. (ADF) is a contractor specializing in deep foundations that is owned and managed, office and field, by individuals who have extensive background and work experience in piles and foundation construction.

SOUTH CENTRAL OFFICE

info@AmericanDeepFoundation.com

EAST COAST OFFICE

GEORGIA OFFICE

info@AmericanDeepFoundation.com

NORTH CAROLINA OFFICE